Reliable. Innovative. Trusted.

Enabling Organization-Wide Innovation

TMA Systems provides facilities and asset management solutions that can be easily configured to your Computerized Maintenance Management Software (CMMS), Enterprise Asset Management (EAM), or Integrated Workplace Management Software (IWMS) needs. For more than 30 years, TMA has provided reliable, innovative and trusted software solutions that help facility executives deliver value by reducing downtime, increasing maintenance productivity, improving equipment reliability and saving money.

Our flagship CMMS solution WebTMA provides all the functionality you need to manage and maintain your capital assets while optimizing maintenance team productivity

Across Industries

Diverse Features

Operational Excellence

Asset Life Cycle Management

Strength in numbers

In the decades that we’ve spent perfecting facility and asset maintenance management software, we’ve helped our customers drive value that reflects in tangible outcomes.

and service across a wide range of industries and applications.

employ our asset maintenance management services across schools, airports, hospitals, banks, state parks, manufacturing facilities and more.

with state-of-the-art preventive maintenance and asset management solutions.

use TMA Systems’ maintenance management solutions to manage and achieve a greater return on their assets.

Facility Maintenance Management

WebTMA enables you to maintain and optimize assets within your facility—equipment, machinery or infrastructure. Plan, schedule, execute preventive maintenance activities to ensure the reliability and longevity of your assets contributing to overall greater Return On Assets (ROA).

Preventive Maintenance

WebTMA enables you to take a proactive approach where equipment and assets are regularly inspected, serviced, and repaired according to a predefined schedule to ensure the increase of equipment reliability. Regular servicing reduces the likelihood of unexpected breakdowns, ensuring that your assets operate reliably. Preventive maintenance can extend the overall lifespan of your assets, saving you money in the long run.

Work Order Management

With WebTMA you can generate and manage work orders seamlessly from creation to completion with quick reference views and our easy-to-use interface. Streamline and automate maintenance processes and schedule preventive maintenance. Submit work order requests for multiple types of services using laptops, desktops, Macs or PCs, tablets, or smartphones.

Preventive Maintenance Library

WebTMA’s Preventive Maintenance Library (PM Library) allows you to create basic templates to use when managing your facility and asset maintenance schedules. It can serve as a reference resource to ensure proactive maintenance measures are consistently applied, minimizing unexpected breakdowns and leading to more predictive maintenance insights while preserving the life of your assets.

Asset Management

WebTMA provides an end-to-end enterprise asset management solution for all your equipment, facilities, machinery, and more with our CMMS/EAM solution for companies of all sizes across industries. WebTMA make it simple for you to keep track of assets with on-demand and preventive work order management tools, comprehensive reporting, and an integrated resource library.

Work Requests

Create work requests with the click of a button. Simple and easy in WebTMA. Each site can enable a portal for users to submit work requests. Work requests serve as the starting point for the maintenance management process, helping teams prioritize and schedule tasks more efficiently.

Geographic Information System (GIS)

WebTMA’s GIS module is a search tool enables visualization of your Work Orders, Requests, and maintenance-worthy items on a map by incorporating spatial data. Visualize, analyze and manage maintenance activities in relation to geographic locations. The integration with ArcGIS provides you with a more customized GIS Map experience. The module helps you streamline workflow processes by allowing maintenance personnel to view existing workloads for geographically-dispersed assets on a map to determine the most efficient method to schedule and perform required work.

Space Management

With the seamless connectivity between WebTMA and AutoCAD, your team is equipped with the most accurate and up-to-date location and space information enabling more efficient maintenance operations. WebTMA’s Space Management module creates a reciprocal relationship between the data in WebTMA and the floorplans in AutoCAD. This offering links location information between both sources, including room numbers, square footage, departmental usage, and more.

Event Management

WebTMA’s Event Management functions provides the capability to create a public facing portal for requesting events as well as a public facing calendar to see what is going on around your buildings or campus. For events that require assistance from facilities maintenance and/or custodians, work orders will automatically be created based on criteria you have set. Effectively manage conflicts for both locations and resources needed for event requests.

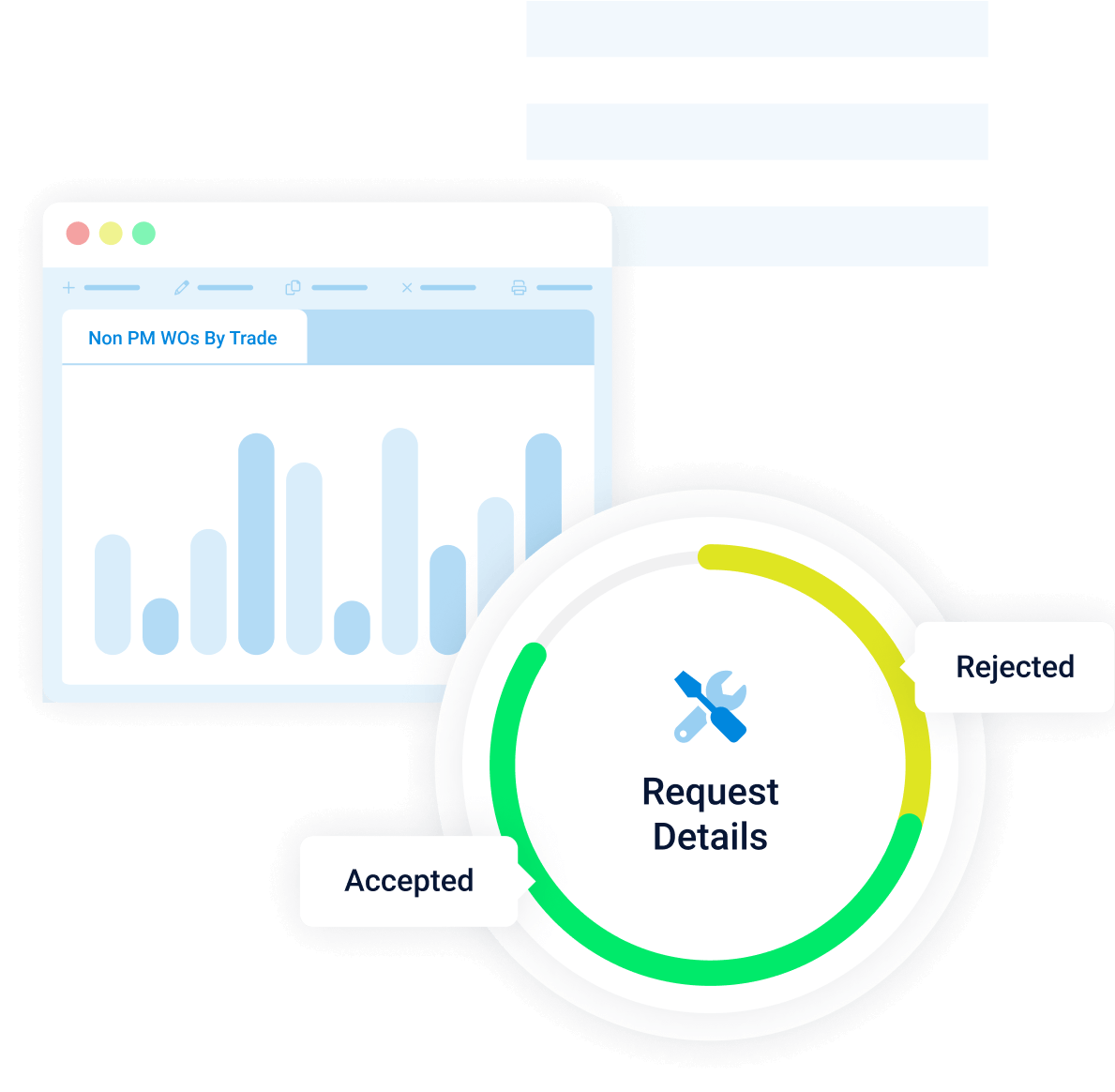

Executive Dashboards

The WebTMA Dashboard features a wide selection of configurable screens that display numerous key performance indicators (KPIs) in a variety of reporting formats. Managers can quickly and easily see the data that is vital to them and their role within the organization – and act upon it seamlessly. The role-specific dashboards are available with the ability to easily create custom views. Access to this real-time data will provide insights, and confidence necessary to make more informed decisions related to operations. With built-in automatic alarms, users are kept up to date when items move outside their thresholds – providing the opportunity to take immediate action.

Task Library

WebTMA enables you to save time using predefined tasks. Create, view, and edit tasks that you can use repeatedly when creating and scheduling work orders and PMs. Having a task library streamlines the planning and execution of routine maintenance and standardizes procedures while ensuring consistency in asset maintenance management.

Multi-Site CMMS/EAM

Does your organization have multiple business sites and locations to manage? No problem. WebTMA, the leading-edge maintenance management solution, ensure full visibility of all your facilities. Centralize and streamline facility and asset maintenance management processes and communication across multiple geographic locations, while enhancing overall maintenance management efficiency.

Mobile Solutions

Conveniently Manage all your facility maintenance activities while on the go with the WebTMA Mobile application anytime, anywhere on your iPhone, iPad and Android devices. Provide technicians with the ability to carry out their work orders and PMs, and complete inspections. Operate online or offline while on the go. When online, the module transmits data directly to the WebTMA database in real-time. When offline, data is stored locally on the device which automatically synchronizes to the WebTMA database once an online connection is available.

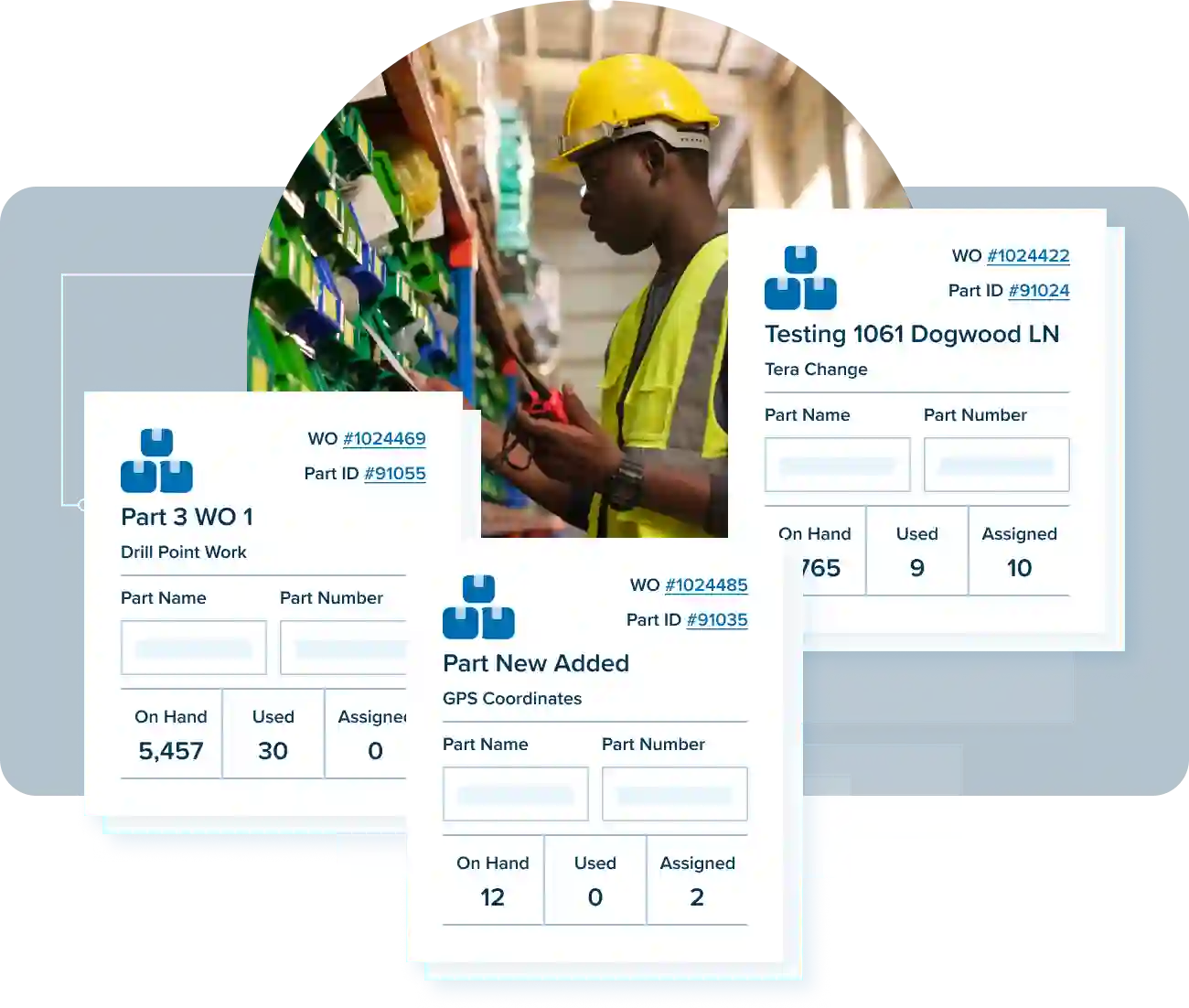

Inventory Management

WebTMA Ensures full control and management of your entire inventory with inventory management capabilities. You can view and manage the inventory of all parts across geographic locations with the ability to view, receive, initiate and cancel site-to-site transfers. Efficient inventory management helps organizations optimize stock levels, reduce downtime, and control costs with robust inventory asset maintenance management.

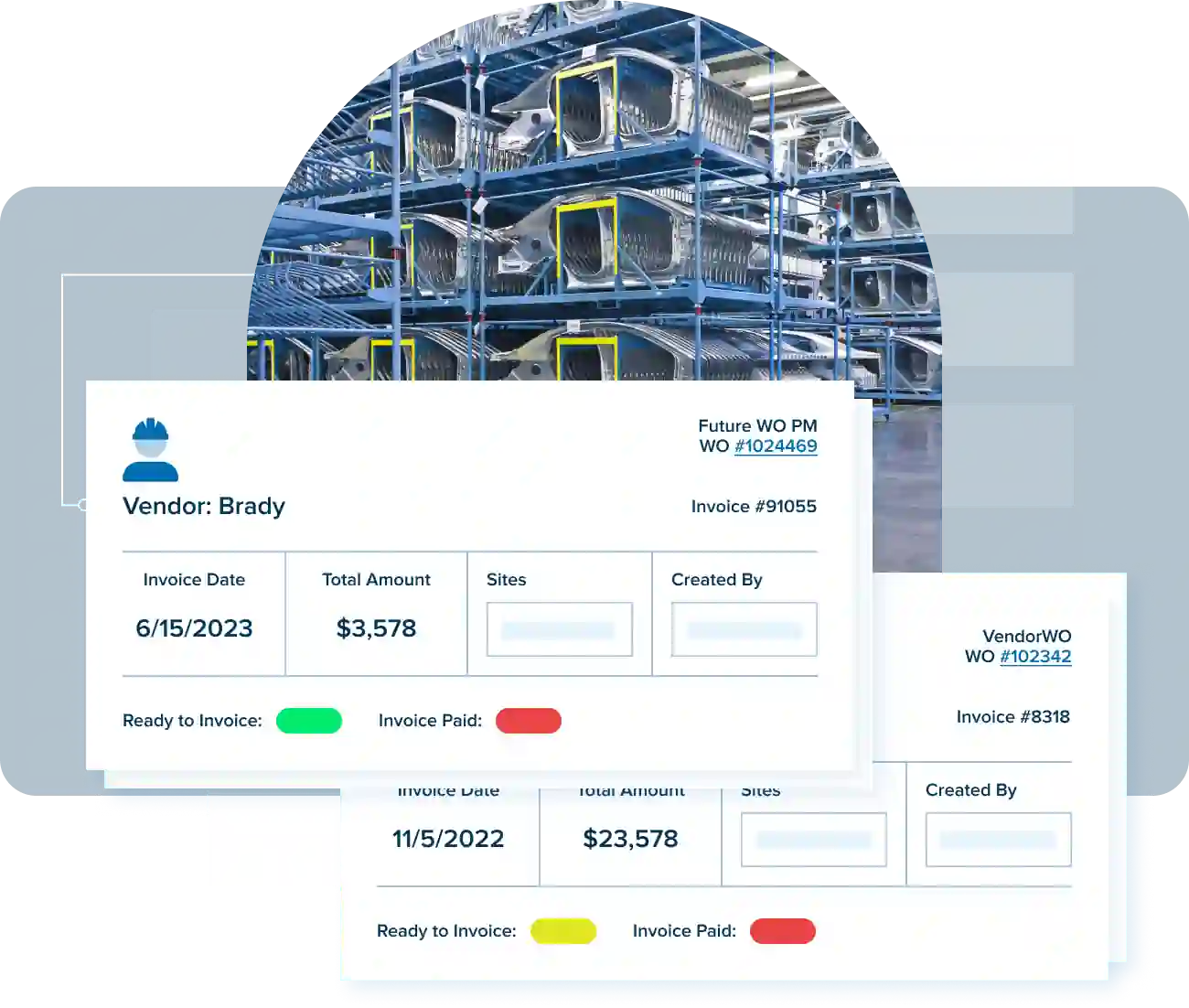

Vendor Management

WebTMA enables a view into external suppliers and services so you can effectively oversee and coordinate interactions with them. You can ensure new and spare parts are always available for asset maintenance and repair. View and manage all the purchase orders for your site and manage external contractors and merchants with our Vendor Management module.

Mass Import Tool

Easily and efficiently upload/import small or large amounts of data into WebTMA. Our Mass Import tool streamlines the initial setup and facilitates updates or additions to data accurately. Mass Import allows you to edit data in place as well as make global changes as easy as find/replace.

Capital Planning

Maximize the ROI of Your Maintenance Practices with the WebTMAs’ comprehensive capital investment planning solution. The Capital Planning module summarizes your enterprise’s capital investment information. Leveraging powerful data processing, the module simplifies this complex data into a visually digestible report, using interactive excel graphs and a variety of pertinent reports. The Capital Planning module can analyze information to support the execution of multiple “what if” models. This helps budget officers and facility managers visually analyze the impact of specific funding scenarios.

Scalability

Grow as your business grows and no restraints. Start with our WebTMA Basic or Plus plans and then add additional functionality through our comprehensive list modules, APIs and Integrations. Hosted in the Microsoft Azure environment, you’ll gain peace of mind knowing that your information is secure, you can expand and grow and have confidence knowing that application will always be available.

Interfaces and Integrations Section

WebTMA's robust platform API's and open data architecture can integrate with your existing business software enabling bi-directional data flow including Autodesk, Esri, SAP, Honeywell, SAP, Oracle and StarRez and more. Bring seamless interoperability, data exchange, and scalability for IoT deployments within your business infrastructure with our APIs, BACnet, Open Blue Enterprise Manager (OBEM) and Aramark Intelligent Workspace Experience (AIWX) integrations. With WebTMA, our intuitive integrations bring unparalleled capabilities and unlimited possibilities for your enterprise.

Modern, Secure Asset Maintenance

TMA Systems’ in-house team of engineers works to continuously optimize the performance of our facilities and asset management solution. Built on modern web architecture, our data infrastructure supports organizations with high security requirements.

Streamlined Operations-

Tangible Outcomes

Our automated workflows enable enterprises to optimize their asset maintenance strategies and focus on essential projects instead of manual tasks. As a result, enterprises can drive real-time Return-On-Investment (ROI) through reliability-centered facilities and asset maintenance management.

Resources

Using data analytics to optimize predictive maintenance schedules

Maintenance has always played a crucial role in ensuring the reliability and efficiency of equipment and machinery. However traditional maintenance strategies, such as routine maintenance or reactive maintenance can be costly and inefficient.

Ready for a Demo?

Interested in taking this to the next level? Sign up for a free demo with a TMA Systems Account Executive. Enter your email below and we will reserve a time for you to test drive WebTMA, or call us at 1.800.862.1130!

.svg)

.webp)

.webp)